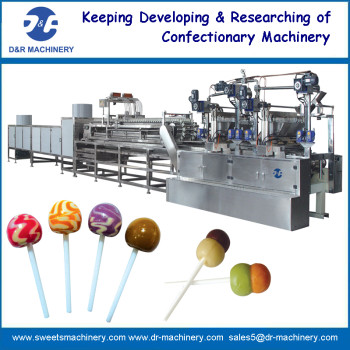

Lollipop depositing machine

- FOB Price

US $128000.01 - 30 set

- group name

- Lollipop making mahcines

- Min Order

- 1 set

- brand name

- D&R Machinery

- model

- DR-BTD

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, Cash

- Export mode

- Have the independent export and import right

- update time

- Thu, 19 Mar 2020 13:15:20 GMT

Paramtents

Condition New

Application Candy

Voltage 380v

Power(W) 35kw

Weight 6000kgs

Dimension(L*W*H) 13mx1.5mx2.5m

Certification ce

Warranty 1year

After-sales Service Provided Engineers available to service machinery overseas

machine LOLLIPOP PRODUCTION LINE

Packging & Delivery

-

Min Order1 set

Briefing

1. WITH AUTOMATIC STICK INSERTION SYSTEM

2. WITH AUTOMATIC DEMOULDING SYSTEM

Detailed

Lollipop depositing machine

| Productioin capacity | 150-450kg(As per 10g candy) |

| Power consumption | 30-45kw |

| Compressed air comsumption | 0.5m3/min |

| Air pressure | P=0.4-0.6Mpa |

| Steam comsumption | 450kg/h |

| Pressure of steam | P<0.7Mpa |

| Water comsumption | 2200L/h |

| Size | 16m(L)x2m(W)x2.7m(H) |

| Weight of machine | 4000kg |

PURPOSE AND CHARACTERISTIC

D&R lollipop depositing plant consists with AUTO-WEIGHING DISSOLVING SYSTEM,MICROFILM COOKER OR MICROFILM ROTARY COOKER ,DEPOSITING MACHINE WITH COOLING TUNNEL AND STICKER INSERTIONSYSTEM.Machine with high automation,high output,better apperance of lollipops,suit for producing single color lollipop,double color double vlavour lollipop,twin ball lollipop,stripe lollipop and so on.D&R also offering the servo driven machine with motion controller system,make the machine more efficiency and easy operation.